Search This Supplers Products:Industrial Videoscope

Application of industrial endoscope/borescope/videoscope/endoscopio in aerospace industry

publisherJEET VIDEOSCOPE

time2022/07/22

- The industrial endoscope products of Shenzhen JEET Technology Co., Ltd. mainly involve the R&D, manufacturing and maintenance of aerospace products; Automobile research and development, production, sales and maintenance; Military industry and security; Track design and manufacturing technology and management of oil and gas chemical industry, ships and railway locomotives; Maintenance of fire system pipelines and sewers.

Application of industrial endoscope/borescope/videoscope/endoscopio in

aerospace industry

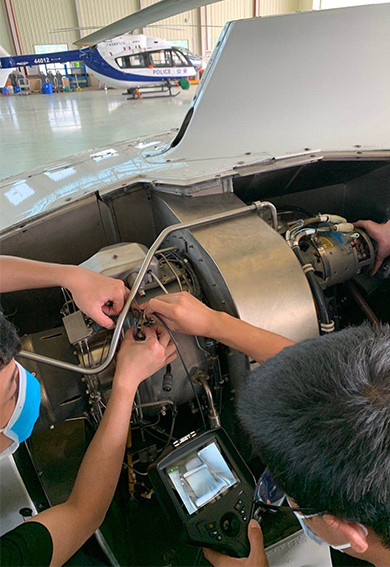

Industrial endoscope is of great significance to the safety and effectiveness of aircraft. Through industrial borescope inspection, the engine disassembly, replacement, transportation and unnecessary shutdown losses are avoided, and the maintenance cost is saved. At the same time, the videoscope observation is intuitive, accurate, easy to operate, and can detect the internal damage of the engine in time. Considering the particularity of aeroengine maintenance, industrial endoscope is mainly used at present. With the help of industrial endoscope, the diesel engine set checks the internal components of the engine, finds the existing damage in time, and evaluates its performance status.

1. Characteristics of industrial inspection camera

Endoscope detection technology can send back the defects on the detection points with clear and high-resolution complete color image data, and can continuously enhance, analyze and store the image problems. When applying industrial endoscopes, the following main factors need to be considered according to the actual situation: first, the size of the inspection hole, second, the path of the detection position. Flexible endoscopes are selected for complex paths, and hard tube endoscopes can be selected for linear paths; The size and location of defects will affect the research image. Because of the complex structure of the aero-engine, routine maintenance cannot always rely on dismantling the engine for detection, so we need to use a borescope to detect it, that is, an endoscope for regular inspection. Fast and efficient inspection avoids a series of costs consumed in the process of engine maintenance.

2. Application of industrial videoscope technology in Aeroengine

In the aerospace field, industrial endoscopes have been widely used in the aerospace field, mainly to detect turbine blades, combustion chamber cracks, find and remove excess materials in the fuselage frame, weld various oil pipes and other cavity surface defects and other pipe surfaces, surfaces, engine cylinder barrels, oil pipes, oil pressure parts, nozzle components, etc. Compared with other detection technologies, the technology of detecting aircraft engine faults with industrial endoscope is relatively simple. The system uses the endoscope probe to transmit the image inside the engine to the external display. The crew judges the fault according to experience and the engine maintenance manual.

The endoscope in aviation is mainly used for quality control of research, design and development, manufacturing, assembly, internal structure welding of aero-engine, inspection of sanding, burr and wrong hole of castings, and defect troubleshooting of key parts such as flight navigation system.

The industrial endoscope products of Shenzhen JEET Technology Co., Ltd. mainly involve the R&D, manufacturing and maintenance of aerospace products; Automobile research and development, production, sales and maintenance; Military industry and security; Track design and manufacturing technology and management of oil and gas chemical industry, ships and railway locomotives; Maintenance of fire system pipelines and sewers. Welcome to inquire about the latest industrial endoscope products in our industry.

Turbine cleaning, blade and nozzle / nozzle blockage inspection, recovery of fallen parts, internal and external corrosion of pipelines, main steam pipelines, water supply heaters, condensers, wind turbines, blade operation status, refining / oil transmission lines and sealing systems, valve base inspection, turbine / generator / generator, generator stator inspection, blade inspection.

Aerospace Industry

Routine maintenance and inspection of large diesel engines, various engines and pipelines in railways and ships. It is used for regular inspection of aircraft turbine, blade, engine, weld surface, duct surface, combustion chamber interior or body inspection, as well as research, development and manufacturing of rocket engine.

Petrochemical industry

There is no need to disassemble the tested equipment in the testing process, so it is a very cost-effective testing solution. Especially in the detection and inspection of internal defects such as storage tanks, heat exchangers, spherical tank trucks in petroleum refineries, pipeline facilities in the chemical industry, special inspection stations and pressure vessel production units.

Automobile manufacturing, means of transportation

Endoscope is also an indispensable daily tool in the cleaning and maintenance of automobile engine. At the same time, it is simple, flexible, compact and easy to carry. The soft, small and flexible insertion tube can reach any hidden part that needs to be checked. Automobile endoscope is widely used in automobile production and maintenance industry. It is mainly used to detect and diagnose the wear, carbon deposition and blockage of automobile engine, cylinder, oil pressure parts, fuel pipe, engine, muffler, transmission and air conditioning system, differential, water tank, oil tank, gearbox, etc., which improves work efficiency, reduces repair costs, and avoids the damage caused by repeated disassembly and assembly of parts.

Locomotive, engineering, pharmaceutical, food pipeline

In railway / ship,inspection camera is used to inspect electric locomotive, air conditioning system, turbine, heater, diesel engine, boiler flame and pipeline. Construction engineering is used to check the corrosion and dirt of steel pipes, internal diagnosis of walls, rust of reinforcement, cracks of support shafts and bridge joints, etc. it can also be used to observe the cavities inside the tunnel and building models; Diagnosis of corrosion and blockage of tap water drainage pipe. Research institutions are used for observation, scientific research, laboratories, archaeology, etc. of research institutions.

Development trend of industrial endoscope

Industrial endoscope technology has unique advantages. It can extend people's sight distance, change the direction of sight at will, and accurately observe the real condition of the inner surface of the object, which cannot be replaced by other detection instruments. For example, in the application of aviation, the industrial camera/videoscope can be extended into the interior of the aircraft engine to directly observe the real internal condition or the internal surface condition of equipment parts after operation; Effectively detect the surface condition of concealed or narrow parts without disassembling the equipment or components for destructive inspection. The method is simple, reliable, intuitive and effective. Whether in the field of aviation, aerospace, electronic industry and other manufacturing In the maintenance industry, the use of endoscope for NDT detection has achieved good results, solved many difficult problems, ensured the normal operation of the whole set of equipment, and avoided some accidents.

Now the application of industrial endoscope technology has developed to the use of computer image processing technology, printing technology and network technology to complete the capture, storage, processing and analysis of images under endoscope, the writing of standardized reports, advanced document management, accurate image measurement and analysis, local enlargement, clear graphic and integrated report output, etc.